Click

on pictures for higher-quality images.

LG08: Oak Axe 2020

The

ultimate farm-to-table luthier's story: A guitar made entirely

of oak I harvested from a tree in the yard. That tale of insanity

can be found below.

I

used the "KD Patent" style of headless nut and bridge that can

sometimes be found on EBay or Amazon. It requires a little wrench

that magnetically attaches to the bridge to tune it--a clever, if

somewhat cumbersome, design. For pickups I went with a pair of

noiseless P90 facsimiles and a low-noise single coil I had leftover

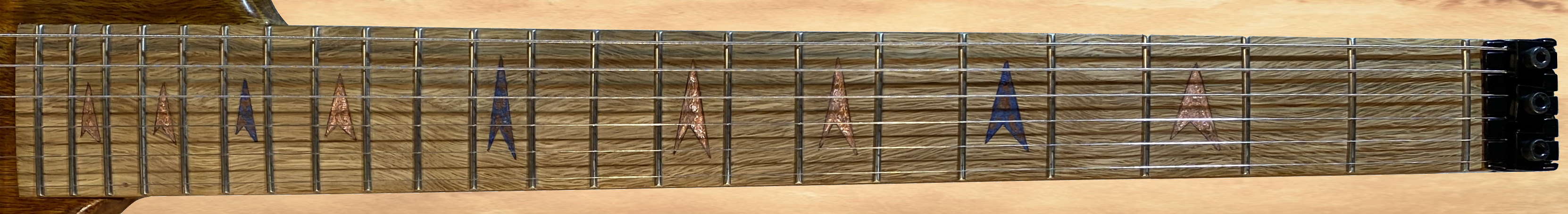

from a previous project, controlled by three off-on switches, one

volume, one tone. Some of the neck position markers are bits of

copper foil crumpled and mashed into routs, flooded with superglue; the

others are blue and copper mica power suspended in Mod Podge, then

flooded with superglue. The body was given a rubbed on dye finish

that I eventually dubbed "potato skin" after seeing the end

result. The neck and body were clear-coated with a UV-curing

resin, then sanded and polished. I cut an instrumental panel

cover for the back out of the same wood and sent it to my brother Rusty

to CNC a logo on that. I filled it with some wood filler and

tried to stain to match the body. Unfortunately, I didn’t

do a great job at that, since the body's stain job morphed so much over

time. But still cool to have the logo.

So how does it sound? The mock P90s probably sound fairly close to the real thing. The bridge pickup is bright, without the snap of a Telecaster. The neck pickup is bright enough to be useful as a rhythm sound, and the two together also present another very useful rhythm sound. The middle single coil is pretty thin in comparison, but a useful sound in its own right. Adding it to one of the P90s gives you much of the vibe of the Stratocaster "in-between" positions, and even all three together sound pretty cool--something you don't often find in three-pickup guitars.

The Tree Story:

By spring 2015 an oak sapling that had grown for a couple decades next to the house had become a modest tree. Unfortunately, its limbs began damaging the roof, and every time you trimmed them they grew back sharper and more problematic. It was also disrupting the air conditioner's foundation, so it needed to come down. This was a bit tricky, since it was surrounded by azaleas, the house, the air conditioner, and a nearby fence, not to mention that about four feet up it made a dogleg, then immediately branched into two trunks. I had to use hand tools and cut it at the dogleg, but I was able to bring it down without any Wyle E. Coyote consequences.

So how does it sound? The mock P90s probably sound fairly close to the real thing. The bridge pickup is bright, without the snap of a Telecaster. The neck pickup is bright enough to be useful as a rhythm sound, and the two together also present another very useful rhythm sound. The middle single coil is pretty thin in comparison, but a useful sound in its own right. Adding it to one of the P90s gives you much of the vibe of the Stratocaster "in-between" positions, and even all three together sound pretty cool--something you don't often find in three-pickup guitars.

The Tree Story:

By spring 2015 an oak sapling that had grown for a couple decades next to the house had become a modest tree. Unfortunately, its limbs began damaging the roof, and every time you trimmed them they grew back sharper and more problematic. It was also disrupting the air conditioner's foundation, so it needed to come down. This was a bit tricky, since it was surrounded by azaleas, the house, the air conditioner, and a nearby fence, not to mention that about four feet up it made a dogleg, then immediately branched into two trunks. I had to use hand tools and cut it at the dogleg, but I was able to bring it down without any Wyle E. Coyote consequences.

At this point, a dehydration-induced fit of insanity burped into existence. Could I turn this into lumber, then build a guitar out of it? It would be a heck of a thing to do, and would serve as a warning to the other trees. Over several days, abusing a number of hand and power tools, I extracted the chin-high stump and harvested the biggest areas of the rest of the tree.

Over the next couple weeks I tortured every ax, saw, hammer, wedge, plane, and power tool I could get my hands on:

…and turned this into slabs of wood:

…then finally into something resembling a pile of lumber:

Wood

is often placed in a kiln to dry to a moisture content appropriate for

woodworking. It turns out that an attic in south Alabama is

pretty much the same as this type of kiln, so I staked the lumber in

the attic for several months until moisture readings reached an

acceptable range. Along the way, as physical recovery outweighed

common sense, other limbs from this and other trees were harvested and

added to the stockpile.

While it's not common, oak has been used by others for guitar construction, so this wasn't a totally off-the-wall idea. My biggest concern was the significant weight, along with the relatively small size of the straight lengths of board I could manage from this pile. I decided the best solution was to make a headless guitar--this would keep the weight down and allow me to use a shorter board for the neck. But obviously I had no plans to go by, so I was making this up from scratch. Knowing I had a limited amount of wood to work with, I figured I should build a prototype out of inexpensive materials first. I ended up building two, as you can see on the home page. I decided to go with the general body design and hardware used in the second prototype, along with some pickups I had set aside for this project. Days of cutting and sanding this petrified oak later, I started to have something resembling a guitar.

While it's not common, oak has been used by others for guitar construction, so this wasn't a totally off-the-wall idea. My biggest concern was the significant weight, along with the relatively small size of the straight lengths of board I could manage from this pile. I decided the best solution was to make a headless guitar--this would keep the weight down and allow me to use a shorter board for the neck. But obviously I had no plans to go by, so I was making this up from scratch. Knowing I had a limited amount of wood to work with, I figured I should build a prototype out of inexpensive materials first. I ended up building two, as you can see on the home page. I decided to go with the general body design and hardware used in the second prototype, along with some pickups I had set aside for this project. Days of cutting and sanding this petrified oak later, I started to have something resembling a guitar.